- Acoustic Imaging Camera

- Amplifiers

- Analyzers

- Antenna

- Cable

- Calibrators

- EMC Tester

- Generators & Sources

- Grid Simulator

- Thermal Camera

- Meters

- Microwave Plasma CVD Systems

- Oscilloscopes

- Partial Discharge Detectors

- Probe Station

- Power Quailty Systems

- Power Supplies & Loads

- Recorders & Dataloggers

- Safety Testers

- Amplifier

Thermal Imaging Camera

Unlike traditional cameras detecting visible light, infrared thermal cameras like the FOTRIC utilize infrared technology to detect and visualize heat signatures emitted by objects and environments. With its exceptional features and highlights, the FOTRIC thermal camera sets a new standard in thermal imaging:

With up to 1280x1024 pixels resolution, ±1% accuracy, and 30mK thermal sensitivity, the infrared thermography camera detects even the subtlest temperature variations. Enjoy crisp and detailed thermal images across the entire field of view, ensuring no anomaly goes unnoticed. Moreover, with <1℃ image uniformity, rest assured of consistent and distortion-free thermal imaging results for precise analysis in industrial, diagnostic, and research applications.

With these advanced features and superior performances, the FOTRIC infrared camera empowers professionals across industries to conduct comprehensive thermal inspections and analyses with confidence and efficiency.

How Does Thermal Imaging Camera Work?

Thermal imaging cameras also referred to as temperature cameras, function by detecting infrared radiation emitted by objects, known as heat signatures. They consist of essential components including a lens, thermal sensor, processing electronics, and mechanical housing. By identifying heat signatures, these thermographic cameras generate images based on temperature discrepancies rather than typical visual appearances.

At the heart of a thermal imaging camera lies the infrared detector, also known as a sensor or focal plane array (FPA). It is highly sensitive to infrared radiation and transforms the emitted heat into electrical signals. Comprising thousands of individual pixels, the FPA enables precise measurement of the infrared radiation emitted by different areas of the scene. The pixel configuration of FPAs typically ranges from 80x80 to 640x480 pixels or more, determining the camera's resolution. This resolution is generally lower than that of visible light cameras due to the longer wavelengths of infrared radiation, resulting in larger sensors in size for thermal imaging.

When an object emits heat, it emits infrared radiation in the form of photons. The pixels of the infrared detector in the thermal camera react and capture these photons and convert them into electrical signals. The strength of these signals is proportional to the temperature of the object, with hotter objects emitting more infrared radiation

Once the electrical signals are generated by the detector, they are processed by the camera's electronics. The camera then assigns each pixel a specific temperature value based on the strength of the electrical signal received from that pixel. This temperature data is then used to generate a thermal image of the scene or the area, also known as a thermal profile or heat map, with each pixel representing a different temperature value.

To enhance the accuracy and reliability of the thermal image, modern thermal cameras often incorporate additional components such as lenses, image processing algorithms, and display screens. The lens focuses the infrared radiation onto the detector, ensuring clear and sharp images. Image processing algorithms analyze the temperature data from the detector and apply enhancements to improve image quality and highlight temperature variations. Finally, the display screen allows users to view and interpret thermal images in real-time.

What Do Thermal Imaging Cameras Detect?

Thermal imaging cameras detect heat, specifically infrared energy, rather than normal light. The capability of the sensor allows them to identify various heat-related phenomena that may not be visible to the naked eye. Even minor variations in heat signatures between objects are distinctly visible to a thermal sensor, regardless of lighting conditions. Therefore, thermal cameras can operate effectively in total darkness or environments filled with smoke. With thermal cameras, users can detect animal presence in the dark, locate pests or rodents within structures, identify overheating components in machinery or electrical systems, and even spot fires before they escalate, which provide valuable insights into heat distribution and anomalies.

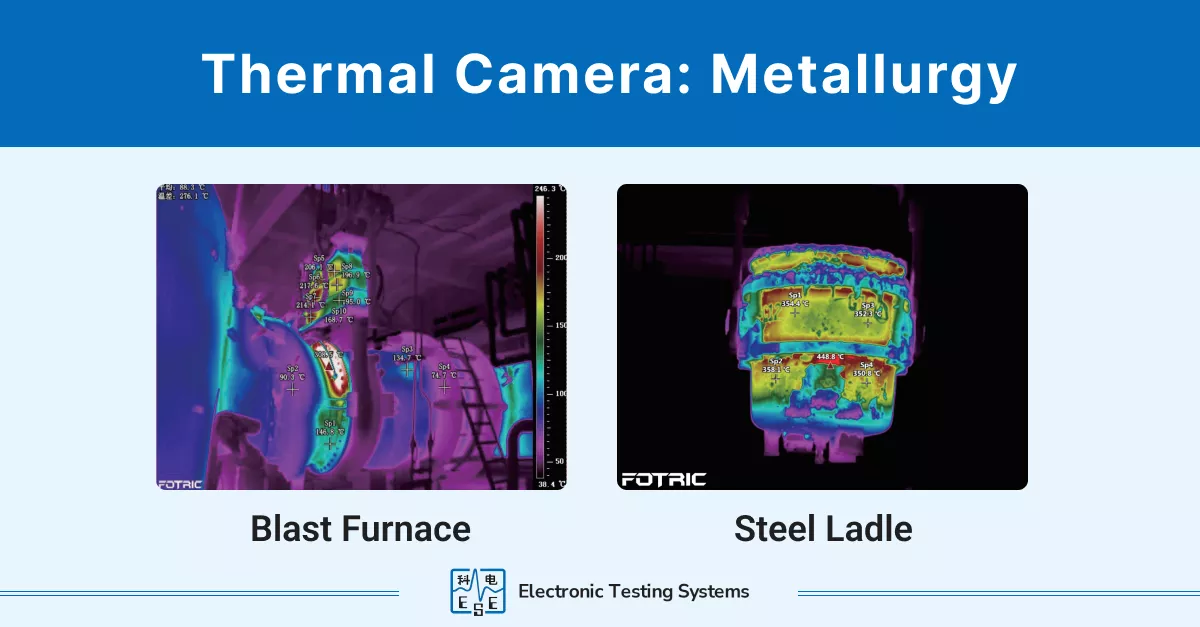

Examples of visualization of heat signatures captured by thermal imaging cameras by detecting heat for metallurgy

Types of Thermal Cameras

Two primary types of thermal cameras are commonly used: cooled and uncooled. The primary difference lies in their cooling mechanisms.

Cooled

Cooled thermal cameras utilize a sophisticated cooling mechanism to maintain the temperature of their detectors at cryogenic levels, ensuring optimal performance and sensitivity. These cameras are capable of detecting extremely low levels of infrared radiation, making them ideal for high-end applications like scientific research, defense, aerospace, and industrial applications that require exceptional image quality, precision, and sensitivity. Cooled thermal cameras typically offer a wider temperature range and higher resolution compared to uncooled cameras.

Uncooled

Uncooled thermal cameras do not require cooling mechanisms and operate at ambient temperature, making them more compact, rugged, lightweight, and energy-efficient compared to cooled cameras. Despite having lower sensitivity and resolution, modern uncooled cameras stand out with high specifications, making them ideal for onsite measurements and R&D purposes. They offer adequate sensitivity and resolution for many commercial and industrial applications, such as building diagnostics, predictive maintenance, security surveillance, and firefighting, providing valuable thermal imaging capabilities at a lower cost.

How to Select the Best Thermal Cameras

When selecting a thermal camera, several factors must be considered to ensure optimal performance and suitability for your specific needs.

Resolution

Resolution determines the level of detail in thermal images. It has to do with the number of pixels in the sensors. Higher-resolution cameras provide clearer and sharper images with high accuracy, making them ideal for detecting small defects in electrical circuits or conducting detailed building inspections.

Sensitivity

Thermal sensitivity (Noise Equivalent Temperature Difference, NETD), measured in mK (millikelvin), indicates the camera's ability to detect temperature differences. A higher sensitivity allows for the detection of smaller temperature variations, crucial for identifying subtle anomalies or defects. For instance, a thermal camera with high sensitivity (e.g., below 50mK) is essential for detecting minute temperature changes in medical thermography applications.

Field of View

The field of view (FOV) determines the area captured by the camera lens. A wider FOV is advantageous for scanning large areas or monitoring expansive spaces, while a narrower FOV offers increased detail and accuracy for focused inspections. Some cameras provide the flexibility to change lenses, offering increased versatility. For example, a thermal camera with a wide FOV (e.g., 45 degrees) is suitable for surveillance and perimeter monitoring, while a narrow FOV (e.g., 10 degrees) is ideal for inspecting small components in electronics manufacturing.

Functionality

Consider the intended use and required features of the camera, such as image storage, video recording, data sharing, or real-time analysis. Choose a camera with functionality tailored to your application needs to maximize efficiency and effectiveness. For instance, a thermal camera with onboard analysis software is beneficial for predictive maintenance tasks, allowing for immediate identification of equipment faults.

Temperature Range

The temperature range of the camera defines the minimum and maximum temperatures it can accurately measure. Ensure the selected camera's temperature range aligns with the expected temperature range of the objects or environments being monitored.

Focus

The camera's focus capability determines its ability to capture sharp and clear images. The focus for thermal imaging cameras normally includes three kinds: fixed, manual, and autofocus. Choose a camera with adjustable focus settings or autofocus functionality to optimize image quality and maintain accuracy across varying distances. For example, a thermal camera with manual focus adjustment is ideal for aerial thermography for solar panel inspections.

Spectral Range

Consider the spectral range of the camera, which specifies the wavelengths of infrared radiation detected. Different materials emit and reflect infrared radiation at distinct wavelengths, making spectral range selection critical for specific applications such as material analysis or gas detection. For instance, a thermal camera with a mid-wave infrared (MWIR) spectral range is suitable for detecting methane gas leaks in industrial environments.

What are the Uses of Thermal Cameras?

Thermal cameras find diverse applications across various industries and fields, offering invaluable insights into temperature variations and heat distribution. From electrical maintenance to building inspections, these advanced tools provide a non-contact method for detecting anomalies and identifying potential issues. Let’s see the common uses of these infrared cameras:

Electrical Wiring Maintenance

Thermal cameras are indispensable for electrical wiring maintenance as they detect hot spots caused by loose connections, overloads, or damaged components. These anomalies, often invisible to the naked eye, indicate potential fire hazards or equipment failures. For instance, a loose connection may lead to arcing, causing electrical fires.

Checking 3-Phase Equipment

Thermal cameras are invaluable for checking 3-phase equipment, which connects to the power supply via 3 wires, as they reveal imbalances in current distribution and detect faulty components such as overloaded circuits or failing motors. For example, an imbalanced load in a 3-phase motor may indicate a damaged winding or connection with temperature differences among the different connections. By identifying these issues early, thermal cameras help prevent equipment failures, ensuring uninterrupted operation and minimizing maintenance costs.

Building Maintenance

Thermal cameras are essential for building maintenance as they detect heat losses, air leaks in HVAC systems, and water intrusion that may lead to structural damage or energy inefficiency. For example, a thermal camera can identify areas of heat loss around windows or doors, indicating inadequate insulation. By pinpointing these issues, thermal cameras help prioritize maintenance tasks, optimize energy usage, and reduce utility costs.

Industrial Inspections

Thermal cameras are indispensable for industrial inspections as they identify equipment malfunctions, leaks, or insulation deficiencies that may compromise safety or efficiency. For instance, a thermal camera can detect overheating electrical components or steam leaks in a processing plant. By visualizing these thermal anomalies, thermal cameras enable proactive maintenance, preventing costly downtime and ensuring regulatory compliance.

First Responders/Rescue Missions

Thermal cameras are indispensable for first responders and rescue missions alike, enabling swift and effective operations in challenging environments. Firefighters rely on thermal cameras to navigate through smoke-filled buildings and locate trapped victims, while search and rescue teams use them to identify heat signatures in hazardous areas like collapsed buildings or dense forests. By providing real-time situational awareness, thermal cameras enhance response times and increase the likelihood of successful outcomes in emergency situations.

Security

Thermal cameras enhance security measures by detecting intruders in low-light conditions or through dense foliage. For example, a thermal camera can detect human presence in a darkened area, alerting security personnel to potential threats. By providing continuous surveillance capabilities, thermal cameras improve perimeter security and safeguard critical assets in industrial facilities, airports, and military installations.

Forest Fire Management

Thermal cameras play a critical role in forest fire management by detecting hot spots and monitoring fire spread in real-time. For example, firefighters can use thermal cameras mounted on drones or aircraft to identify areas of intense heat, allowing them to prioritize firefighting efforts.

Contact Us For Your Special Requirements

As we progress, we remain dedicated to providing our valued customers with top-tier products. We are steadfast in our commitment to meeting all your thermal imaging needs, offering unparalleled quality and support. Don't hesitate to reach out to us for further details about our uncooled thermal cameras or to place your order. We are your trusted thermal imaging camera supplier, ready to assist you every step of the way.